Pressure Testing in detail

Pressure testing can take place in various ways including hydrostatic, air under water and decay tests.

All welded tube assemblies are 100% pressure tested to at least 2 x safe working pressure. Nylon assemblies are typically decay tested.

Oil flushing is available to ensure high levels of cleanliness. Video examples of the various types are shown here.

Products

Manipulated Tube

Materials typically include Stainless, Carbon Steel, Copper, Brass and…

Find out more

Fabricated Tube

Using a wide range of commercial materials hydraPower offer a comprehe…

Find out moreCase Studies

HydraPower and our products have been involved in numerous projects. Take a look at the following case studies for working examples of our technology.

CERN - Hadron Collider

The CERN tunnel is 27km (Nearly 17 miles) in circumference and lies in certain places up to 160 Metres below the earth’s surface.

Read Case Study

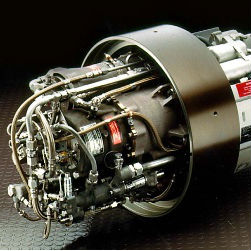

Spearfish Torpedo

The Spearfish torpedo (formally Naval Staff Target 7525) is the heavy torpedo used by the submarines of the Royal Navy.

Read Case StudyAccreditations of the highest standards

TS502514

FM1171

EMS 623050